From the Winamac Republican 29 January 1919

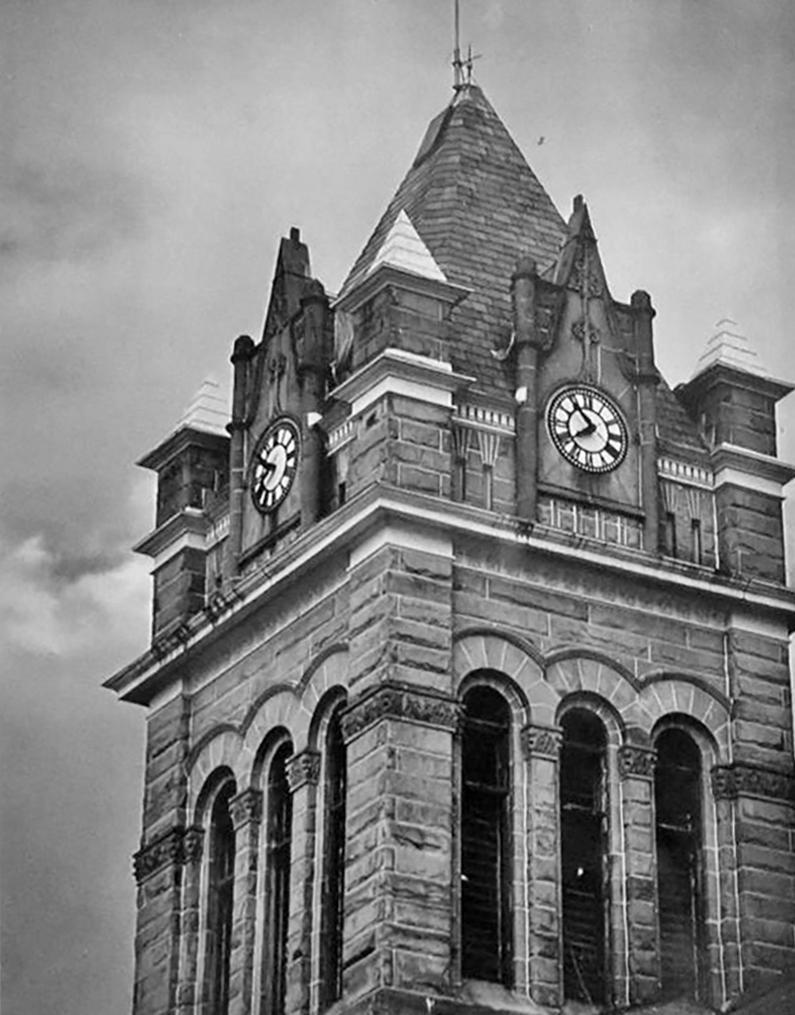

Who is not familiar with the big courthouse clock, yet how few of us really know anything about its mechanism. The clock is a curiosity in many ways. It is almost as big as a small thrashing machine.

Who is not familiar with the big courthouse clock, yet how few of us really know anything about its mechanism. The clock is a curiosity in many ways. It is almost as big as a small thrashing machine.

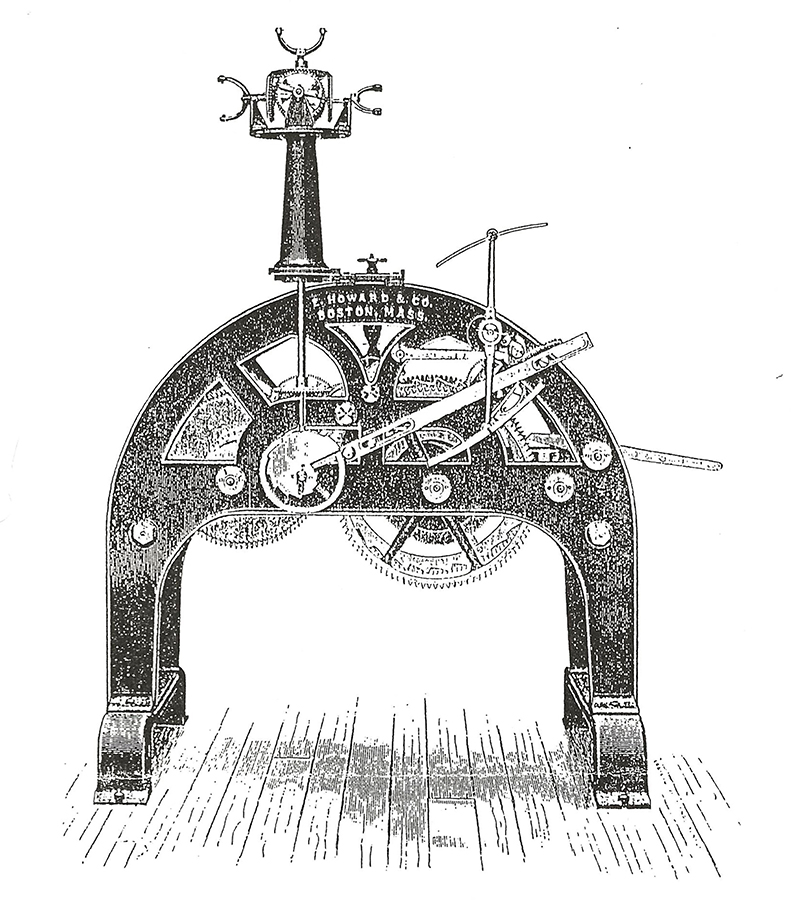

The frame looks like two immense inverted horseshoes, about four feet high, an upright shaft extending above this with a bevel cog wheel on which four other bevel wheels turn, each connected to a dial.

The weights which are the first thing one meets in climbing the stairs to the clock, travel a distance of 40 feet, held by quarter-inch steel cable. The running weight weighs 1,000 pounds and the striking weight 1,400 pounds. The weights are large wooden boxes filled with stones.

The running cable or cord is wound onto a cylinder 6 inches in diameter, and the striking side only a cylinder 12 inches in diameter, and it takes about 20 minutes to wind up both sides. The tick wheel measures 4 ½ inches across and the pendulum rod is 10 feet long, making a strike every four seconds.

The gong or bell is another feature of interest. It weighs about 1,000 pounds, is about 3 feet across the bottom and 3 inches thick. Etched on it is, “E. Howard W. & C. Co., , Boston, New York,” and at the top and moulded [sic], “Buckeye Bell Foundry.”

The gong or bell is another feature of interest. It weighs about 1,000 pounds, is about 3 feet across the bottom and 3 inches thick. Etched on it is, “E. Howard W. & C. Co., , Boston, New York,” and at the top and moulded [sic], “Buckeye Bell Foundry.”

The hours are struck by a banner weighing about 15 pounds arranged with springs which causes the hammer to rebound. A small rod connects the hammer to the clock.

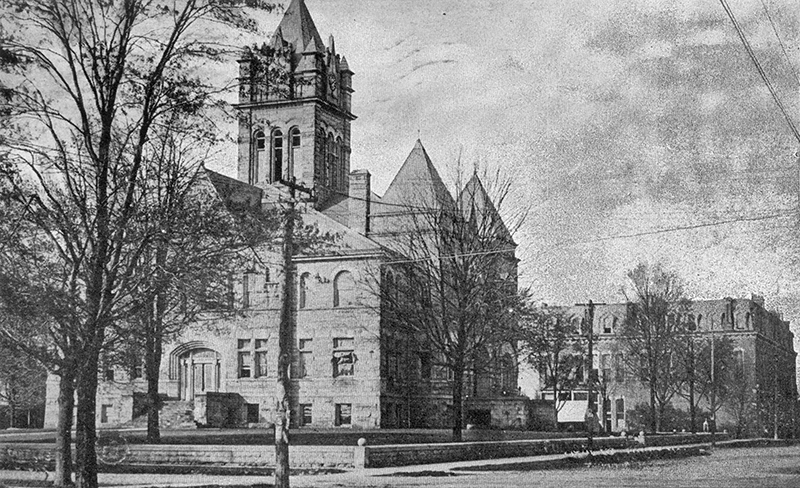

From Commissioners Notes 6 September 1895

In relation to the acceptance of the New Court House the full Board in company with the Architect A.W. Rush looked over the Building and being fully informed on all matters pertaining thereto, decided to accept the building without the clock, the price of said clock ($300.00) to be deducted from the contract price of the building and said contractor is hereby released from all further responsibility on account of the contract for the erection and completion of said Court House Building.

But They Still Needed A Clock

The courthouse here still needed a clock. The one offered by Gibson had cost $300, and the line on expenses had to be drawn somewhere. The clock finally installed cost $700 – but it was the principle of the thing!